CARGO CONTAINMENT SYSTEMS

A cargo containment system is an overall arrangement for containing cargo including, where fitted:

- A primary barrier (the cargo tank),

- Secondary barrier (if fitted),

- Associated thermal insulation,

- Any intervening spaces, and

- Adjacent structure, for the support of these elements.

For cargoes carried at temperatures between -10°C and -55°C the ship’s hull may act as the secondary barrier and in such cases, it may be a boundary of the hold space. The basic cargo tank types utilized on board gas carriers are in accordance with the list below:

Independent tanks

Independent tanks are completely self-supporting and do not form part of the ship’s hull structure. Moreover, they do not contribute to the hull strength of a ship. As defined in the IGC Code, and depending mainly on the design pressure, there are three different types of independent tanks for gas carriers: these are known as Types ‘A’, ‘B’ and ‘C’.

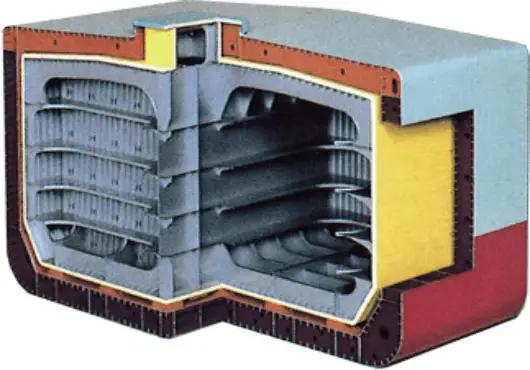

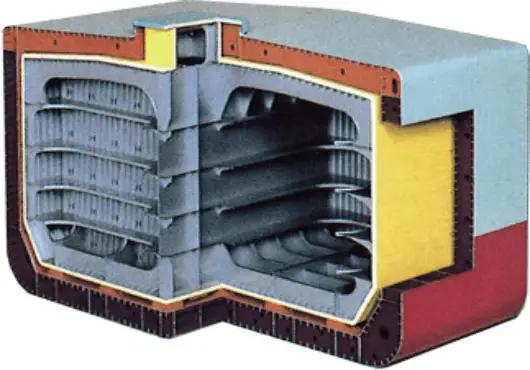

Type ‘A’ tanks

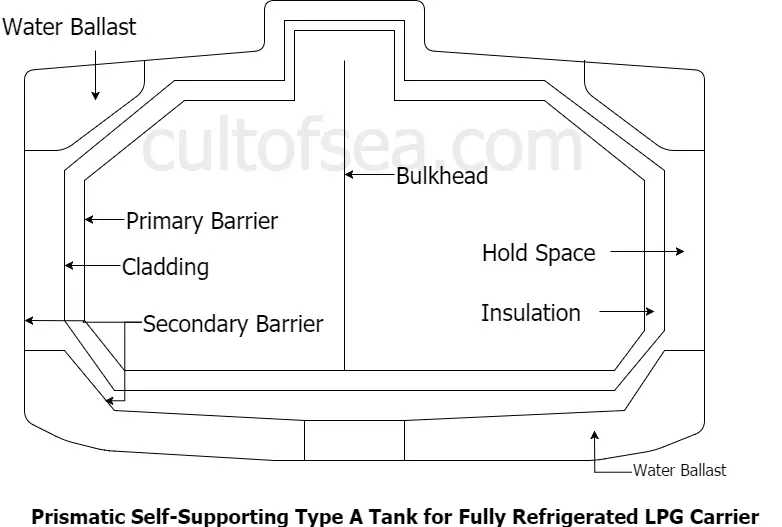

Type ‘A’ tanks are constructed primarily of flat surfaces. The maximum allowable tank design pressure in the vapour space for this type of system is 0.7 barg; this means cargoes must be carried in a fully refrigerated condition at or near atmospheric pressure (normally below 0.25 barg).

Figure below shows a section through this type of tank as found on a fully refrigerated LPG carrier. This is a self-supporting prismatic tank which requires conventional internal stiffening. In this example the tank is surrounded by a skin of foam insulation. Where perlite insulation is used, it would be found filling the whole of the hold space.

The material used for Type ‘A’ tanks is not crack propagation resistant. Therefore, in order to ensure safety, in the unlikely event of cargo tank leakage, a secondary containment system is required. This secondary containment system is known as a secondary barrier and is a feature of all ships with Type ‘A’ tanks capable of carrying cargoes below -10°C.

For a fully refrigerated LPG carrier (which will not carry cargoes below -55°C) the secondary barrier must be a complete barrier capable of containing the whole tank volume at a defined angle of heel and may form part of the ship’s hull, as shown in the figure. By this means appropriate parts of the ship’s hull are constructed of special steel capable of withstanding low temperatures. The alternative is to build a separate secondary barrier around each cargo tank. The IGC Code stipulates that a secondary barrier must be able to contain tank leakage for a period of 15 days.

On such ships, the space between the cargo tank (sometimes referred to as the primary barrier) and the secondary barrier is known as the hold space. When flammable cargoes are being carried, these spaces must be filled with inert gas to prevent a flammable atmosphere being created in the event of primary barrier leakage.

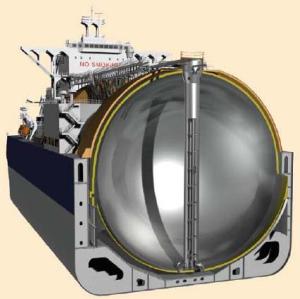

Type ‘B’ tanks

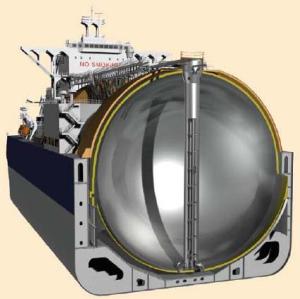

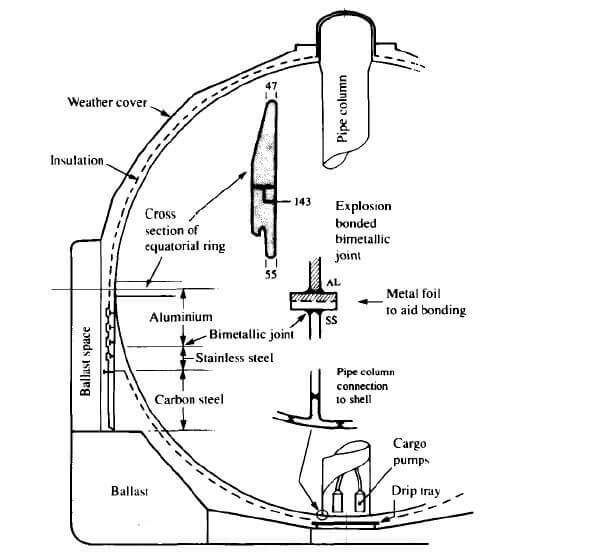

Type ‘B’ tanks can be constructed of flat surfaces or they may be of the spherical type. This type of containment system is the subject of much more detailed stress analysis compared to Type ‘A systems. These controls must include an investigation of fatigue life and a crack propagation analysis. These tanks may be able to withstand pressures up to 2 barg. The most common arrangement of Type ‘B’ tank is a spherical tank as illustrated in Figure 3.2. This tank is of the Kvaerner Moss design. Because of the enhanced design factors, a Type ‘B’ tank requires only a partial secondary barrier in the form of a drip tray. The hold space in this design is normally filled with dry inert gas. However, when adopting modern practice, it may be filled with dry air provided that inerting of the space can be achieved if the vapour detection system shows cargo leakage. A protective steel dome covers the primary barrier above deck level and insulation is applied to the outside of the tank. The Type ‘B’ spherical tank is almost exclusively applied to LNG ships; seldom featuring in the LPG trade.

A Type ‘B’ tank, however, need not be spherical. There are Type ‘B’ tanks of prismatic shape in LNG service. The prismatic Type ‘B’ tank has the benefit of maximising ship hull volumetric efficiency and having the entire cargo tank placed beneath the main deck. Where the prismatic shape is used, the maximum design vapour space pressure is, as for Type ‘A tanks, limited to 0.7 barg.

Cross Section View of Type B Tank Ship

Type B Tank being installed into ships hold

Spherical Tank IMO Type B

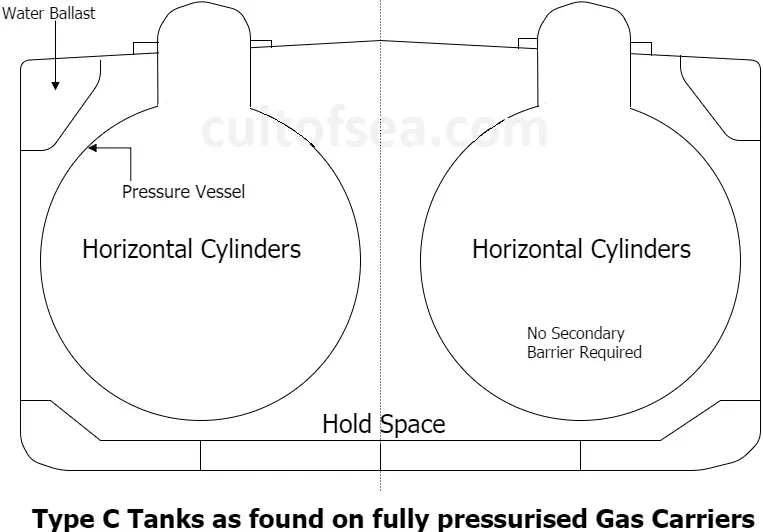

Type ‘C’ tanks

Type ‘C’ tanks are normally spherical or cylindrical pressure vessels having design pressures higher than 2 barg. The cylindrical vessels may be vertically or horizontally mounted.

This type of containment system is always used for semi-pressurised and fully pressurised gas carriers. Type ‘C’ tanks are designed and built to conventional pressure vessel codes and, as a result, can be subjected to accurate stress analysis. Furthermore, design stresses are kept low. Accordingly, no secondary barrier is required for Type ‘C’ tanks and the hold space can be filled with either inert gas or dry air.

In the case of a typical fully pressurised ship (where the cargo is carried at ambient temperature), the tanks may be designed for a maximum working pressure of about 18 barg. For a semi-pressurised ship the cargo tanks and associated equipment are designed for a working pressure of approximately 5 to 7 barg and a vacuum of 0.5 barg. Typically, the tank steels for the semi-pressurised ships are capable of withstanding carriage temperatures of -48°C for LPG or -104°C for ethylene. (Of course, an ethylene carrier may also be used to transport LPG.)

Figure below shows Type ‘C’ tanks as fitted in a typical fully pressurised gas carrier. With such an arrangement there is comparatively poor utilisation of the hull volume; however, this can be improved by using intersecting pressure vessels or bi-lobe type tanks which may be designed with a taper at the forward end of the ship.

A Type C Tank being installed.

A ship under construction in shipyard with IMO Type C Tanks

Membrane tanks (membrane – 0.7 to 1.5 mm thick)

The concept of the membrane containment system is based on a very thin primary barrier (membrane – 0.7 to 1.5 mm thick) which is supported through the insulation. Such tanks are not self-supporting like the independent tank & an inner hull forms the load-bearing structure. Membrane containment systems must always be provided with a secondary barrier to ensure the integrity of the total system in the event of primary barrier leakage. The membrane is designed in such a way that thermal expansion or contraction is compensated without over-stressing the membrane itself.

There are two principal types of membrane system in common use

- Gaz Transport membrane system

- Technigaz membrane system

Both named after the companies who developed them and both designed primarily for the carriage of LNG.

Initially, the Moss system was more popular, but higher Suez toll fees due to their higher gross tonnage made Moss vessels less attractive for trades involving the Suez Canal. Recently Moss has staged a comeback and currently, there are about 30 Moss vessels on order against 100+ membrane vessels. A fourth LNG containment system joined the ranks of the large marine LNG cargo tank designs in the early 1990’s; the Japanese IHI SPB (Self-supporting Prismatic shape IMO type-B) system. With only two orders for LNG carriers in the 1990’s, this system seemed to be inaccessible due to its high price. However, in 2014 four vessels were ordered with the SPB system, bringing it back as a credible alternative to the membrane systems and the Moss system.

Membrane systems

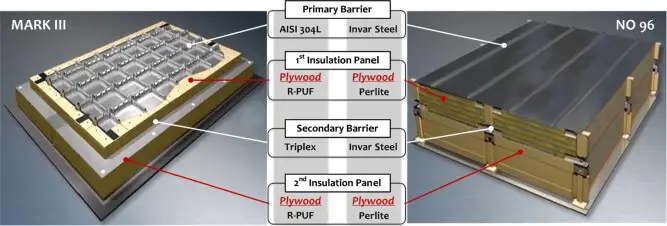

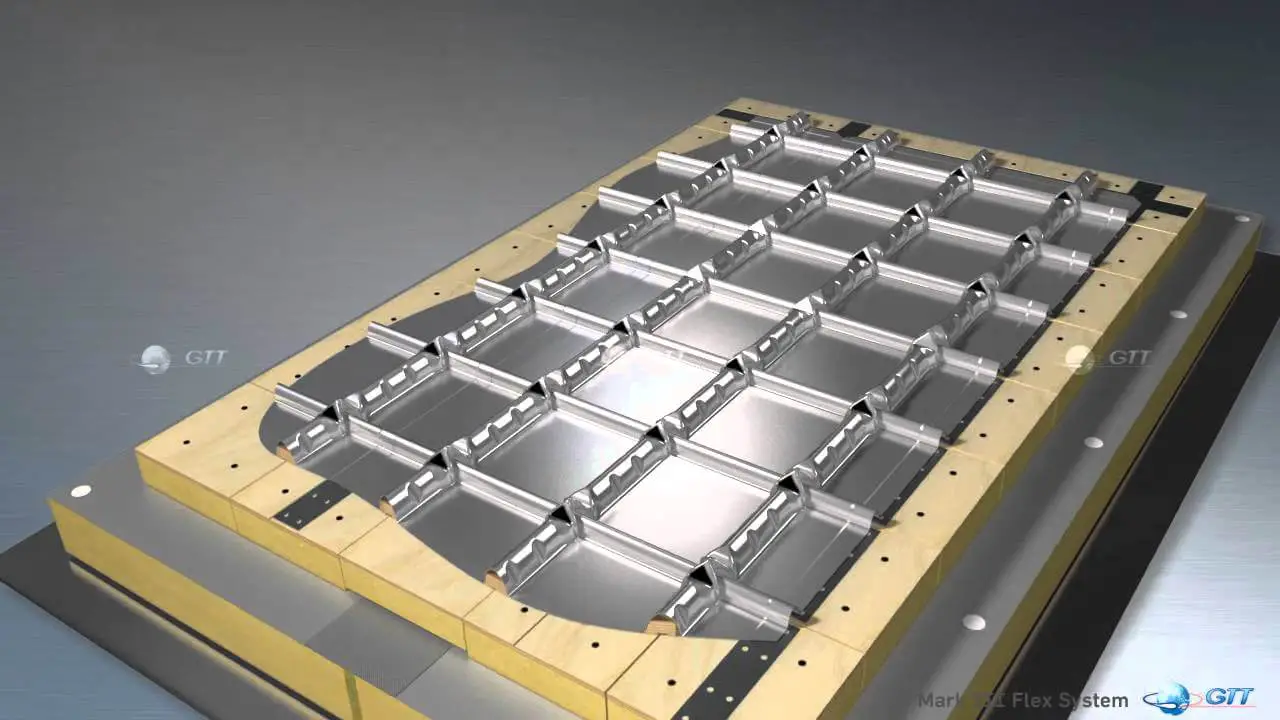

Technigaz designed a membrane type atmospheric LNG containment system with a corrugated stainless steel primary membrane supported by wooden boxes filled with insulation material. A secondary cryogenic barrier, also supported by wooden boxes filled with insulation material provides containment of the cryogenic cargo in case the primary membrane develops a leak. The characteristic corrugations in the primary membrane allow for the shrinkage of metal under cryogenic temperatures. This design, identified as the Mk I was soon superseded by improved versions and is currently available as the Mk III series from a number of shipyards in Korea and Japan. Soon the Mk V series will be going into production, which replaces the current Triplex secondary barrier with a corrugated stainless steel secondary barrier.

Compatriot Gaztransport designed a rather similar system consisting of a primary membrane supported by insulation in plywood boxes and a secondary membrane, also supported by insulation in plywood boxes. This system was called the No 88 system and featured a primary and secondary membrane of a steel alloy with a negligible contraction coefficient. Improvements have been over the years and the current system is the No 96, which is being used in LNG carriers under construction in Korea and China.

After years of competition, Gaztransport and Technigaz merged to form GTT, which has been developing and promoting both membrane type containment systems in parallel. GTT has licensed these systems to all major LNG carrier builders around the world. The main advantage of the membrane type containment systems is their prismatic shape, which allows these systems to use the space available within the hull of the LNG carrier to a very high degree. With the cargo tanks recessed deep inside the hull under a low trunk deck, membrane type LNG carriers do not need a high deck house to have good visibility. This results in the typical “squat” silhouette of this type of vessels. In France, GTT proposed membrane type LNG fuel tanks for the proposed newbuilding ferry for Brittany Ferries. Unfortunately this project was put on hold for the time being for non-technical reasons.

Both membrane systems have one traditional weakness; their vulnerability for sloshing damage. Sloshing is the motion of the LNG cargo in the tanks as a result of the motion of the vessel due to the effect of waves and wind. In certain circumstances, waves occur in the LNG cargo which upon impact on the tank walls can cause damage to the primary barrier and the boxes supporting the primary membrane. To counter the risk of sloshing damage, GTT advises the operators of membrane ships to operate their ships with tank levels of more than 90% or less than 10%. For applications that require part load operations, such as LNG Floating Storage and Regas Units (LNG FSRU), membrane systems with specially reinforced boxes have been developed.

Gaztransport Designed Membrane Tank featured a primary and secondary membrane of a steel alloy with a negligible contraction coefficient.

GTT-technology membrane tank model fabricated by Conrad Shipyard.

Cross Section of a Technigaz showing each layer

Technigaz designed a membrane type LNG containment system with a corrugated stainless steel primary membrane supported by wooden boxes filled with insulation material.

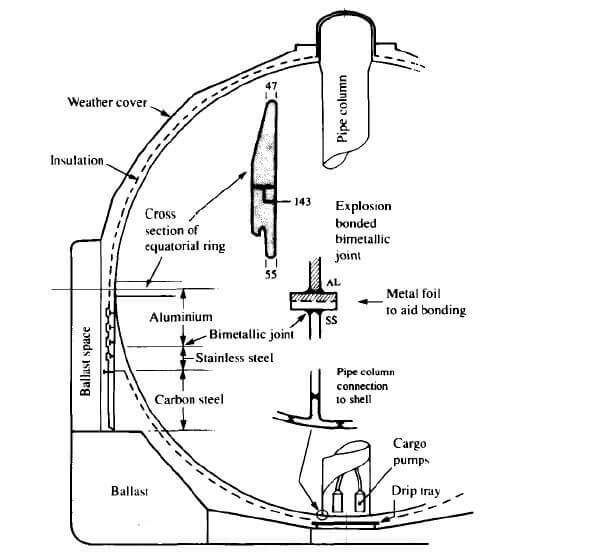

The Moss system

The Moss spherical LNG containment system does not have these sloshing issues. Its aluminium spheres have sufficient structural strength to withstand LNG wave impact due to the interaction between the cargo and the ship’s motion. The Moss system doesn’t need a full secondary barrier like the membrane system; there is only a small drip tray below the spheres to catch any liquid leaking. The design philosophy behind the Moss system is that the tank should be designed to be strong enough so that cracks should not develop in the tanks over the lifetime of the vessel. The structural strength of the containment system is exactly the reason why old Moss vessels are very popular candidates for conversion to LNG FSRU’s or even floating LNG production plants.

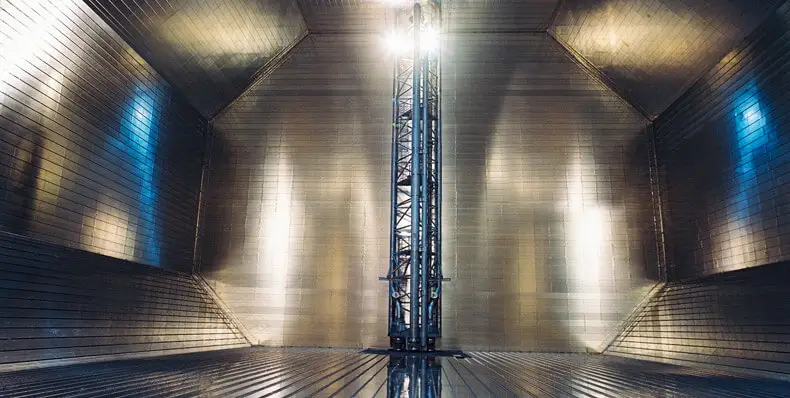

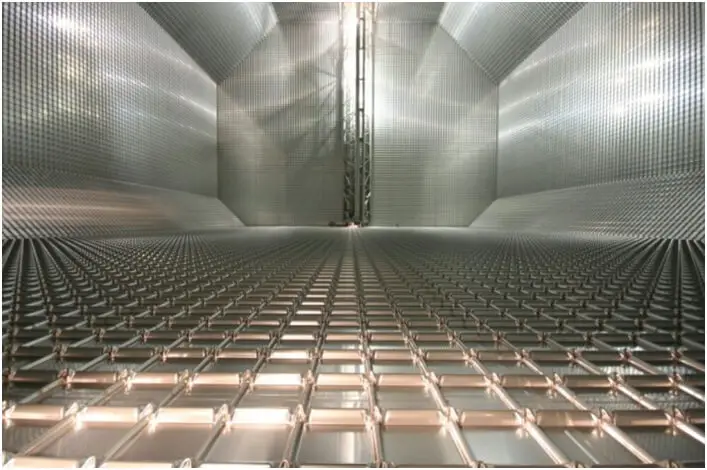

View from inside of Tank

View from inside the hold of ship

The only true disadvantage of the Moss vessels is the fact that the containment system has a very low hull space utilization rate. The sheers are mounted on the deck of the vessel by way of an equatorial ring, which means that half the sphere protrudes above the deck. While this makes for the characteristic silhouette of the Moss carrier, it also necessitates a high deck house to ensure adequate line of sight from the bridge. The low hull space utilization means that a Moss carrier has a higher GT rating than membrane carriers of similar cargo capacity, which translates in higher port and fairway dues and higher tonnage taxes.

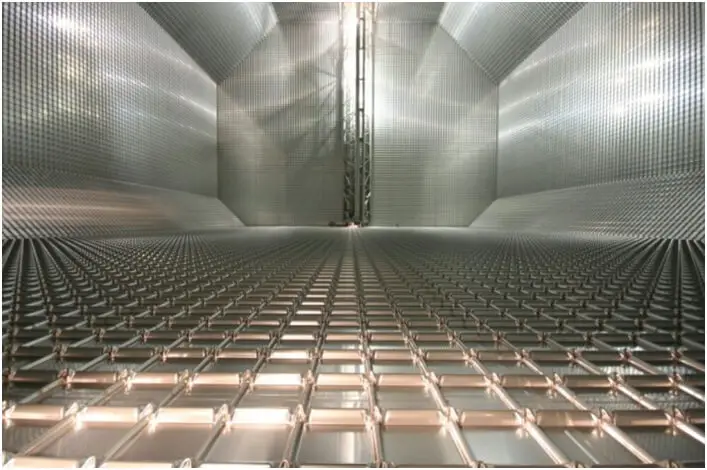

The SPB system

The fourth LNG cargo containment system, the IHI (now JMU) SPB system manages to combine the advantages of the membrane system and the Moss system and addresses the disadvantages of both systems too. The prismatic shape of the tanks ensures a high hold space utilization rate and a low air draft, while the solid aluminum construction with a centerline bulkhead and transverse swash bulkheads reduces liquid motion in the tanks and minimizes the risk for sloshing damage, even in part load conditions. The high price of this system originally prevented wide spread adoption but in 2014 JMU, the successor to SPB designer IHI, secured orders for tanks for four 165,000 m3 LNG carriers and it has been addressing the only true disadvantage of this system; its price tag. With possible licensing overseas, the SPB system could become a very serious contender in the LNG containment system arena. In Japan, JMU has already carried out a study with a shipyard into the feasibility of SPB tanks as LNG fuel tanks.

A SPB Tank designed by IHI Japan

A SPB Tank designed by IHI Japan

“IHI-SPB” (Self-supporting, Prismatic Shape, IMO type B) is Japanese own technology developed by IHI Group while the competing technologies used for LNG floaters including LNG carriers by Japanese and Korean shipyards are imported from Europe (Norwegian Moss technology and French Membrane technology). “IHI-SPB” has unique features of “No Sloshing” which enables any level loading of LNG inside the tank at offshore, “Flat upper deck” which enables installation of the topside plants on upper deck, “Less and Easy Maintenance”, etc. and is most suited to use in the LNG floaters including FLNG and FSRU required to stay offshore and operate safely for long years without dry docking.

Integral tanks

Integral tanks form a structural part of the ship’s hull and are influenced by the same loads which stress the hull structure. Integral tanks are not normally allowed for the carriage of liquefied gas if the cargo temperature is below -10°C. Certain tanks on a limited number of Japanese-built LPG carriers are of the integral type for the dedicated carriage of fully refrigerated butane.

Internal insulation tanks

Internally insulated cargo tanks are similar to integral tanks. They utilise insulation materials to contain the cargo. The insulation is fixed inside ship’s inner hull or to an independent load-bearing surface. The non-self-supporting system obviates the need for an independent tank and permits the carriage of fully refrigerated cargoes at carriage temperatures as low as -55°C. Internal insulation systems have been incorporated in a very limited number of fully refrigerated LPG carriers but, to date, the concept has not proved satisfactory in service.